Wax Assembly Strain Gauging

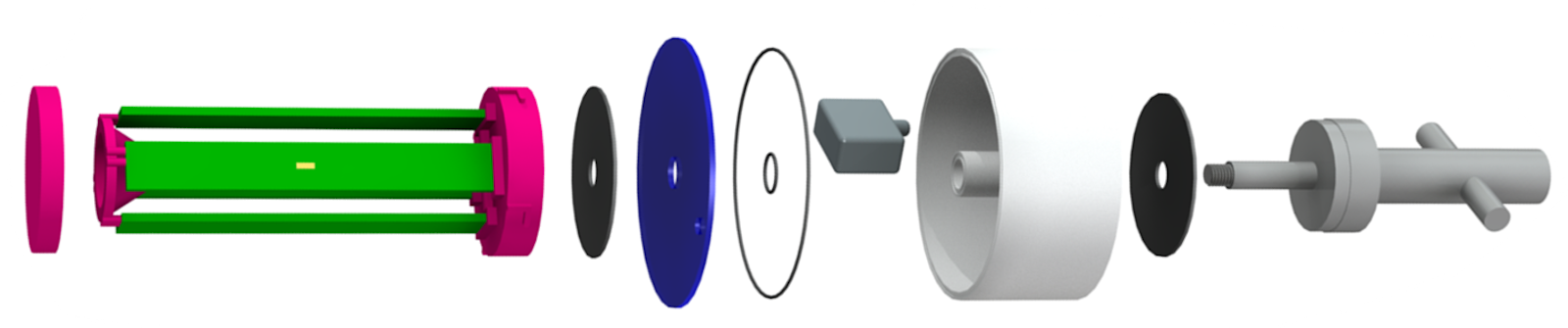

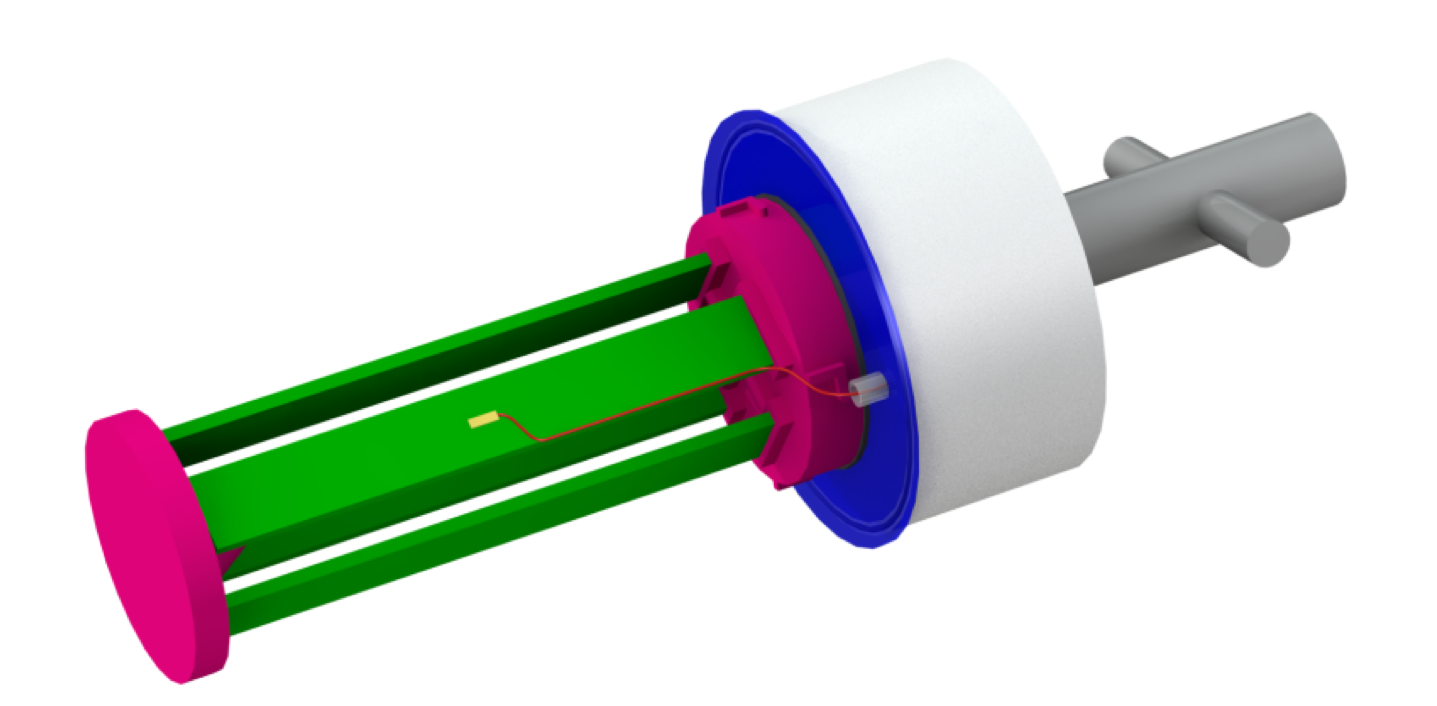

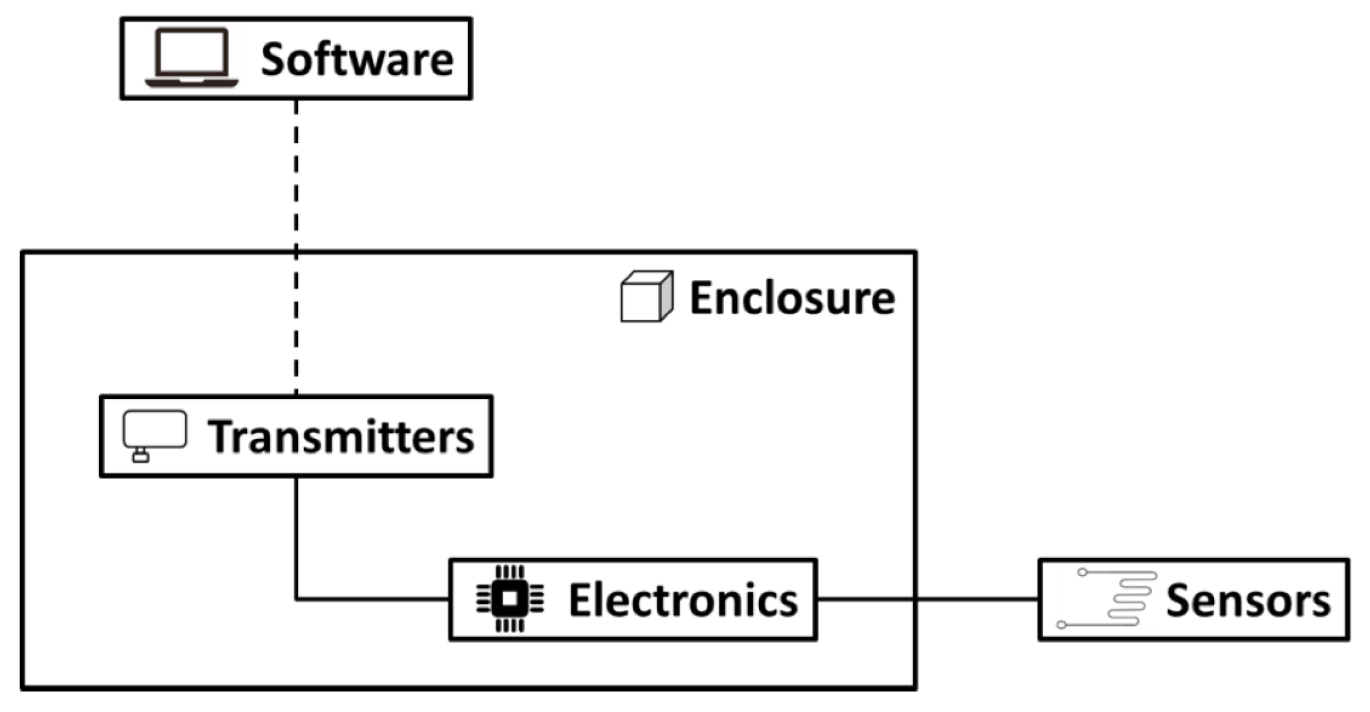

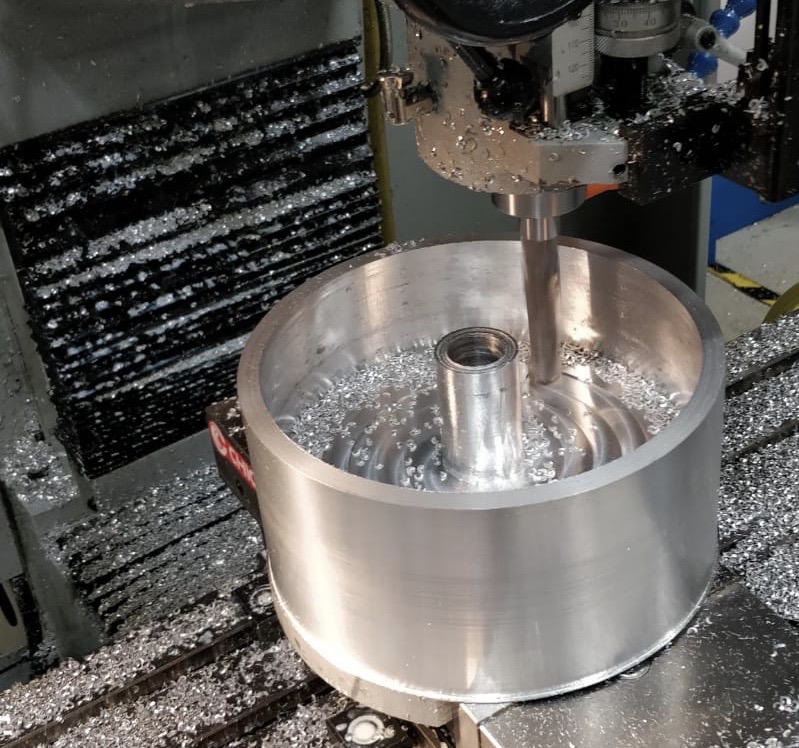

In a small team of engineers, I undertook a Design & Make project at the High Temperature Research Centre, with an aim to develop an experimental method of measuring strain on turbine blades during the investment casting process.

My responsibilities within the team involved:

- Leading the systems engineering activities, ranging from gathering requirements to concept selection.

- Planning and desiging experiments, and analysing data to provide stakeholders with information needed for process improvement.

My first task was to interact with the client and other relevant stakeholders to define and finalise the project and system requirements. I then worked with the team to determine logical system architecture, divide accountabilities, and generate a suitable concept for the strain-measuring system. Having defined the requirements, design of experiments was my main responsibility. This involved specifying design details (geometries tested, location of strain gauges), conducting the experiments (interfacing with lab technicions, monitoring results), and data analysis (processing and analysing large amounts of straing data using MATLAB).

With a team of 4 and short timescales of 13 weeks, the project successfully delivered a fully functional, and easy to use experimental strain-measuring system, together with complete documentation.